Automatic Petrolem Tank Dewatering

Understanding and managing fluid levels in crude storage tanks is vital to cost efficiency. Excessive water in tanks not only reduces valuable storage capacity, but also leads to tank corrosion. Water can be discharged manually, but this process has several drawbacks. It uses valuable man hours. And, as operators lack an accurate understanding of water levels within the tank, dewatering must be based on human observation. This process is inefficient and leaves the possibility that operators will leave water in the tank or allow hydrocarbons to escape through the water draw-off, an expensive environmental liability.

By using water cut meters inserted into the tank or placed on the draw-off line, operators can gain the intelligence required to automate the tank dewatering process. This significantly increases the efficiency of the process while also eliminating the risk of any hydrocarbons escaping via the draw-off line.

Automatic Tank Dewatering Configurations

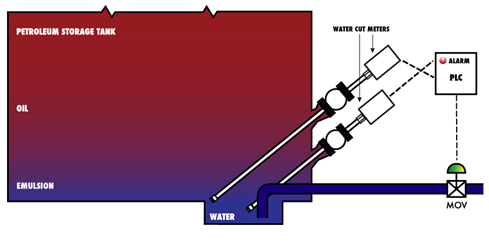

Multiple configurations exist for automating dewatering with water cut meters. The ideal set up is to insert two probes into the tank with the sensors at or near the tank sump but above the water draw-off outlet. As a tank is dewatering, the emulsion layer descends in the tank. When it reaches the bottom or near the bottom, the first sensor detects the presence of hydrocarbons and communicates with a PLC. The PLC then closes a motor operated valve on the dewatering line and the dewatering process stops. Water levels then gradually rise in the tank, and when the sensor once again reads 100% water, the valve opens and dewatering resumes.

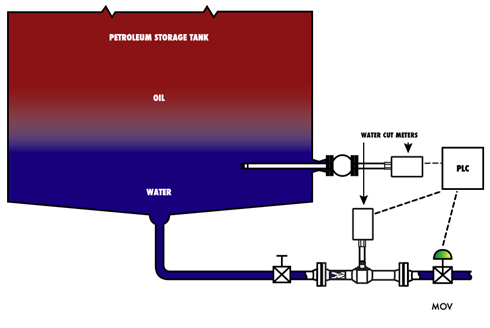

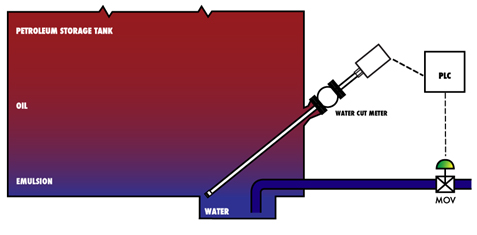

The second sensor, placed below the first, operates as a backup and an alarm should the first sensor fail. In this way, the second sensor would still detect the hydrocarbon layer and trigger the closing of the MOV prior to any hydrocarbons entering the draw-off line. The second, back-up sensor could also be placed directly on the draw-off line. Or, the system could operate with a single sensor, though it would lack an alarm capability.

Automated Tank Dewatering with Alarm

Automated Tank Dewatering with Alarm Sensor on Draw-off Line

Automated Tank Dewatering without Alarm

Sensor Considerations

One problem with automated systems is that paraffins or tank sludge can accumulate on the sensor and affect the accuracy of its measurement. Sensor bodies should be highly polished, and preferably solid body, in order to minimize this effect. However, in some tanks, a maintenance schedule may need to be established.

© Copyright 2025 automatic-tank-dewatering.com